How to Assemble & Operate A Triple Vending Machine

1. Introduction to Your Triple Vend Machine

We would like to congratulate you and give a little friendly advice about your new bulk candy machines. First, please make sure you go through all your boxes in the first three days following delivery to insure your order is complete with no damage occurred during shipping. Then please read these instructions carefully to fully understand your machines better. The paperwork should include:

- a schematic of the machine (showing parts),

- adjustable stock candy wheel,

- adjustable gumball wheel (if applicable to your order) and

- instructions for the stand.

Moving Parts: There are only 3 moving parts in the 3-head triple vending machine. We would like to go over them with you to help keep your machines working their best and lasting longer.

- The lock and Key

- This is a two piece part and should never be over-tightened. The machine, being an all-metal machine, is secure when the lock is snug. The lock is made with 6 metal pins that determine the combination of the lock. When the lock is over-tightened it puts undue pressure on these pins and may cause damage to them. If damage occurs the pins will seize and not allow the lock to come undone. Do not over-tighten the locks.

- Turning the key requires compression of the internal springs. The pins in the lock that make up the code are normally pushed upwards by springs. When the key is inserted, it depresses both the springs and the pins forming the code, thus allowing the lock to turn. These springs will continue to put pressure on the key, pushing the key upwards. You need to make sure the key is always depressed so that the lock turns smoothly. If the key gets hung up due to incorrect compression, either the key or the pins may break. Pay close attention to this so that the key does not freeze up in the lock or break, rendering it unusable.

- Make a record of your key code. The key comes with a code engraved on the flat part of the neck of the key. There are 2 locks and 2 keys per machine. Note the number(s) engraved on the neck of the key in a secure location, in case you ever lose your keys. For us to help replace the locks and keys, you will need to identify the number or code of your key.

- Grease the locks. The locks will last longer if you take some food grade machinery grease like AMSOIL X-Treme Food Grade Grease NLGI#2, with a tooth pick, and put some grease in the thread area of the lock. This will allow the lock to go on smoother and not get stuck due to over-tightening. This process is mandatory and will help with wear and tear on the locks and keys and only needs to be done once. (You can find the food grade grease on Amazon.com)

- The Candy Wheel and Gumball/Toy Wheel with Brush Plate

- These wheels can be set for the amount of candy or size of round gumballs/toys that you would like to dispense.

- Read the instructions provided to understand how the product wheels work and how to work on the 3 product canisters in each machine.

- The Coin Mechanism

- Once a year (depending on usage) or as often as needed, you should tighten up the screws on the back of the coin mechanism. Make sure you do not over-tighten these screws. Making them snug is all that is needed.

- The coin mechanism is a high quality all-metal mechanism that is made so that if a smaller coin such as a penny, nickel or dime is inserted, it can easily be removed with a smaller finger and not jam the mechanism.

- Make sure you read the instructions about the mechanism so you are able to work with the mechanisms if the occasion requires.

2. Assembly Instructions

The height of the stand has been designed carefully. The height of the stand was designed for good visibility so it's easy to be seen and used by customers of any age. The stand being 26 inches tall is the most popular height of any stand in the industry. If it were any taller the machine would become top heavy.

-

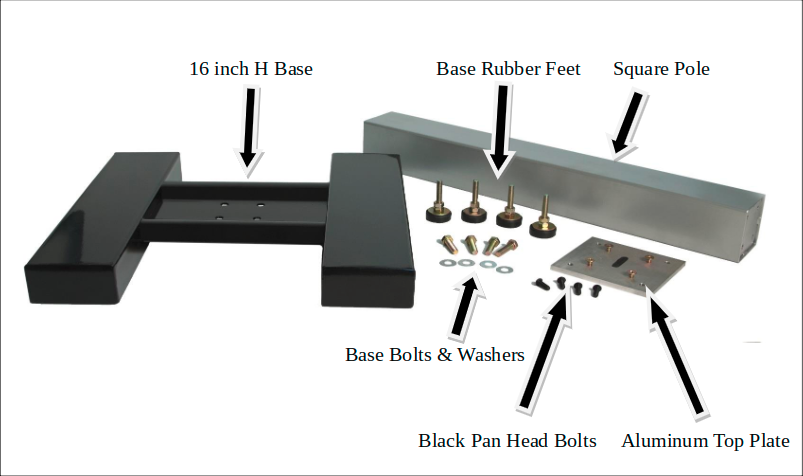

Step 1: Assemble Parts and Tools

Open the box and inventory each of the items before assembling. Each box will include:

- One H-shape Base measuring 15 ¾ X 16 1/2 inch

- One Center Pole measuring 23 1/2 inch (With a square end with 4 screws and an end with an Aluminum Plate with 8 screws in it),

- One stand for each machine.

Tools Needed to Assemble the Stand to the Machine: Phillips Screw Driver & Adjustable Wrench

-

Step 2: Attach Center Pole to Base

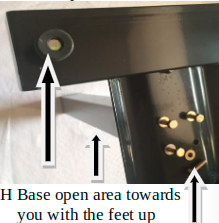

Once you have checked and know you have all the parts, it is very important to follow the instructions carefully. We have already assembled the part of the stand we call feet. They are the 4 rubber parts sticking out of the H-shaped base and they hold the base up. (Those are what sits on the floor and allows you to adjust them to make it so the machine is more stable. You adjust them by unscrewing them and then tightening the one nut in place to the H-shaped Base to keep them from moving.)

Remove post from the box and then with the Aluminum Plate facing down, and the color sticker away from you, and the 4 gold screw facing up, remove the 4 gold screws and the washers.

As you turn the stand upright the open area of the H-shape stand should be facing you and the oblong cut-out hole in the aluminum top plate should be going front to back and not side to side. This oblong hole allows the 2 gold screws in the bottom of the machine to slide in allowing the machine to sit flat on the stand. Take the 4 gold screws out of the aluminum plate.

-

Step 3: Attach Machine to Pole & Base

Remove machine from its box and then remove the keys taped to the bottom of the machine, remove the lid lock and back door lock, set the keys aside. Remove the lid and remove the 3 canisters out of the machine. Open the back door of the machine and take out the coin tray.

Place the machine body on top of the stand and adjust it so the 2 gold screws on the bottom of the machine slide into the oblong hole in the aluminum plate on the stand. Looking through the back door, line up the 4 holes in the bottom of the machine with those holes from which you removed the 4 gold screws, then put the 4 gold screws back in. Tighten them down with a screw driver.

-

Step 4: Attach Candy Tray

Now that the machine and the stand are finished it is time to put on the candy tray. Take the plastic bag off of the candy tray and you will find a bag of hardware that includes: 4 more gold screws, 3 silver screws, 3 wing nuts, and 3 washers. Take the 4 gold screws out of the bag and leave the rest of the hardware in the bag. It is not needed for this step. (The other hardware left will be spoken about later in the appendix "How to lock your globes into place")

Have someone hold the candy tray in place while you put the 4 screws down through the bottom of the machine and into the pre-tapped holes of the candy tray.

Adjust the tray so it is centered and against the front of the machine. Snug the screws down to hold it in place. Do not screw the screws down too tight because the threads in the candy tray are plastic.

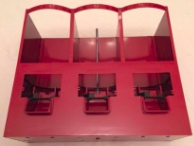

3. Canister Instructions

-

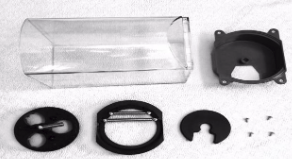

Any Canister may include the items shown here:

-

Candy & Snack Canister comes with

- the clear canister,

- the hopper that the Candy Wheel sits in,

- the Candy Wheel,

- Candy Brush Plate and

- the 4 screws that hold the canister together.

-

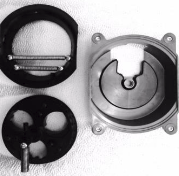

Gumball & Toy Canister: comes with

- the clear canister,

- the hopper that the Gumball / Toy Wheel sits in,

- the Gumball / Toy Wheel,

- Gumball / Toy Brush Plate and

- an extra flat piece we call a Pac Man piece, and

- the 4 screws that hold the canister together.

-

To take apart the Canister you look down the clear canister and you will see 4 screws.Remove the 4 screws, then remove the canister, and the Hopper piece that holds the product dispensing wheels will then separate.

-

You may then remove the first piece, which is the part with the springs, and is called the brush plate. This is the part that brushes away all the extra product out of the dispensing area. The dispensing area of the wheel then moves the product to the drop area (located under the springs and in the front of the hopper and Canister) to dispense the product. You will see the hole in the bottom of the hopper where the product drops through.

Candy/Snack Assembly

Gumball/ Toy Assembly

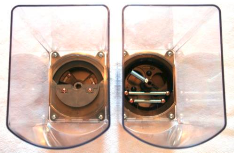

- You may then remove the candy wheel or the gumball wheel. You will see on the top of the candy wheel or gumball wheel that there are 3 screws. If you remove these screws you can then move the adjustable part of the wheel and make the dispensing area bigger or smaller depending on the size and quantity of product you want to dispense. Once you have the adjustable part of the wheel set where you want it put the 3 screws back in to hold the adjuster in place.

- If you are working with the gumball / Toy wheel you will also see a flat piece resembling Pac Man that sits in the hopper under the gumball wheel. The mouth part of the Pac Man piece surrounds the product drop area. This Pac Man piece is also a part of the adjustment of the gumball wheel. If you choose to use larger product than a 1" gumball you must then remove the Pac Man piece so that the product can sit down far enough in the gumball wheel to allow the brush springs to pass over and brush all other product away. Please note, the Pac Man piece is never used with the candy wheel.

- When putting the wheels back in the hopper you must remember the following: For the candy / snack wheel set put the candy wheel in first. Then place the brush plate with the 8 vertical springs over the top of the candy wheel with the spring area to the front of the hopper and over the product drop area. For the gumball / toy wheel and 2 horizontal spring brush plate place the Pac Man piece in the bottom of the hopper first so the product drop area and the open area of the pac man piece match up. Place the gumball wheel in next. It should fit nicely around the center raised area in the hopper and spin freely. Then place the 2 horizontal spring brush plate over the product drop area and towards the front of the hopper. Remember the brush plate has 2 functions. 1st is to brush away any extra product giving a proper vend each time. 2nd is to cover the product drop area so that the candy or gumballs do not flow out of the machine freely.

- Once the wheels, brush plates, and with gumballs / bouncy balls the pac man piece, are in place you then place the canister back on top of the hopper area with the round part of the canister and the drop area in front, match up the 4 holes and replace the screws in the 4 corners.

-

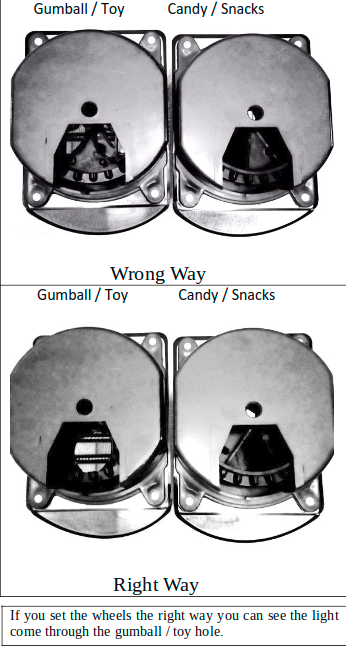

Final Step: Lining up the Dispensing Wheel:

It is very important that once you get the wheels adjusted to the desired portion size and the canister put back together that you line up the product dispensing area so that it is over the product drop area when you place the canister back into the machine. You do this by lifting up the canister while completely assembled and look at the hole or drop area at the bottom of the hopper. The area where the candy or gumball sits should be located in the center of the hole or drop area of the hopper. This way once the coin mechanism makes its complete rotation the product dispensing area will be in the center of that hole or product drop area allowing all products in the dispensing area to fall down the product chute. This must be done each time you remove the canisters!

4. Machine Break Down & Assembly

- The 3-in-1 triple vending machine is the best machine ever built. It has just enough selections to put in a nice location and meet everyone's need. The 3-in-1 machine is made of strong steel with the finest polycarbonate non-shatter canisters. Durable all-metal coin mechanisms meet the task of any location. The 3-in-1 machine was designed to make servicing easy. With removable canisters, 1 secure easy-to-use cash drawer and a hinged door on the back of the machine. You can be in and out of your locations quickly.

- The machine is made up of the following parts:

- 2 Barrel Lock and Key Set

- 1 Lid

- 3 Product Canisters

- 3-in-1 Metal Machine Body

- 3 all-metal Coin Mechanisms

- 3 Product Chute Doors

- 3 Coin Mechanism CoinDiverters: 2 short, 1 long

- 1 Cash Drawer

- 1 Candy Tray

- 1 Machine Stand Complete

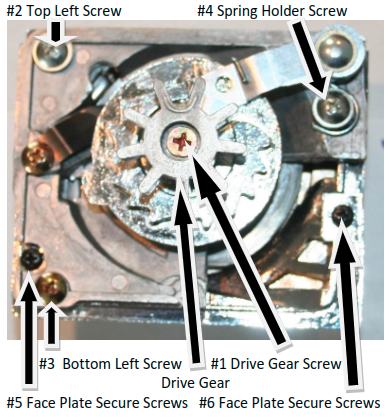

5. Coin Mechanism Assembly

- Front of Coin Mechanism

- Back of Coin Mechanism

- It is rare to need to take apart a coin mechanism. Here are the instructions, with the pictures needed to follow, to make sure you do it correctly. Here are all the coin mechanism component parts:

- The first thing to do to take a part a coin mechanism will be to remove the 6 screws holding the coin mechanism together by going through the coin door in the back of the machine. They are numbered and labeled as follows:

- #1 is the drive gear screw located in the center of the mechanism. This goes from the drive gear in back to the coin mechanism handle in front.

- #2 is the Top Left Screw

- #3 is the Bottom Left Screw

- #4 is the Spring Holder Screw

- #5 & #6 Face Plate Secure Screws (never remove these screws unless you are changing out the coin wheel and coin height tester)

- Next would be to remove the drive gear by lifting it away from the coin mechanism handle. There is Lock Tite placed on the threads to help the screw stay in place. It is generally green. Leave the Lock Tite in place for when you put the mechanism back together. Once you have removed the screws and the drive gear you need to remove the handle. Slightly tap the center square.

- Once you remove the handle you can then remove the back plate which will expose the inside of the coin mech, the Coin Wheel, and coin height tester in the top left hand corner. Very Important: There will be no springs exposed and no worry in losing important parts. If you take the height tester apart make sure you pay close attention on how to put it back together. There is a spring and other small parts.

- Once you are to this point everything about the Coin Mechanism is exposed. If you ever need to do something with the Coin Mechanism it can all be done at this time.

- To re-assemble the Coin Mechanism you will need to place the Coin Height Tester back in place and replace the 2 screws holding it in. Test the plunger arm until it goes up and down smoothly. The plunger Arm tests the height of a coin. Put the Coin wheel back in place and replace the back plate of the mechanism.

- Once to this point you may replace the Coin Mechanism Back Plate and screws #2, #3, and then #4. Replace them in that order.

- Put the Coin Mechanism Handle back in place by going through the front of the mech. Then place the Coin Mechanism Drive Gear back onto the Coin Mechanism Handle that is sticking through the Coin Mechanism Back Plate that you can see by looking through the back of the machine. You will see a U-Shape on the Coin Mechanism Drive Gear. That should be in the UP position as shown in this picture.

- Once you have the Drive Gear in place put in #1 screw to hold the mechanism completely together. This should complete the assembly of the mechanism. It is important to try a quarter through the mechanism before installing the coin mechanism back into the machine.

-

6. Dispensing Wheels & Alignment

Your Canisters are Set Up Candy-Gumballs-Candy, in that order

- CANDY

You should be able to sell most products without adjusting the candy wheel in your machine. The wheels have been set to what the larger national vending route owners use in their machines. -

- 1" GUMBALLS OR 27mm BOUNCY BALLS

-

- CANDY

You should be able to sell most products without adjusting the candy wheel in your machine. The wheels have been set to what the larger national vending route owners use in their machines. You get 1 extra Candy / Snack Wheels per Machine that you may swap out if you do not want to sell Toys or Gumballs. -

- Proper alignment is very important because misalignment can cause your machines to give out free candy and/or grossly uneven amounts per sale. Alignment is typically a simple process; however, make sure you understand it because it needs to be done every time the machine is serviced. The best way to check your machine's alignment is to follow this step-by-step process:

- Turn the canister upside down so that you are looking at the bottom of the hopper. The hopper has a large notch cut out of it. Through this notch, you can see the bottom side of the candy or gumball wheel. The bottom side of the candy or gumball wheel is made up of six, wedge-shaped, compartments. Three of the compartments sometimes have a tip of a screw poking through it, these are just dead space and are unimportant. Here the alignment is correct, as shown in the picture:

- The other three compartments are called the Candy or Gumball Wells. This is where the candy or gumball falls into. Rotate the candy or gumball wheel so that one of the three wells is centered in the notch that has been cut out of the hopper.

- Now turn the canister right-side- up and look in the top. You should see two empty candy wells visible in the bottom of the canister. With the candy or gumball wheel in this position, the machine is perfectly aligned.

- Please remember that the machines will sometimes mis-align themselves while you are servicing them. Always as a final check, visually ensure proper alignment before you replace the canister back in the machine. Of course, with the canister full of candy or gum, you will not be able to look in the top to ensure alignment. Instead you will have to look at the bottom side of the candy or gumball wheel. Once a machine is locked it cannot mis-align itself.

7. Adjusting the Candy and Gumball Wheels

- Lift the canister from off of the machine and set it down on the table. Make sure to empty any candy or gumballs from the canister. Using a 12 inch long Phillips screwdriver remove the 4 corner screws you see when looking down into the canister. Lift the canister off of the hopper and set it down on the table.

- Lift off the candy or gumball brush plate from the hopper. The candy brush plate has 8 vertical springs. The gumball brush plate has 2 horizontal long springs. Set the brush plate on the table. Take out the candy or gumball wheel and place it where it can be worked on.

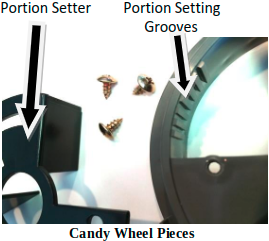

- Using a Phillips screwdriver, remove the (3) Phillips head screws located on top of the candy or gumball wheel. Set them where you will not lose them. Lift off the candy portion setter that the screws were holding in place. Move the candy portion setter to the right for smaller portions and to the left for larger portions of candy. Drop the candy portion setter in the chosen slot/groove and replace the (3) Phillips screws to hold the portion setter in place. On the gumball portion setter you do not have to remove it. You may just slide the portion setter back and forth to set the size of product you want to dispense and then tighten the (3) screws to lock the portion setter in place.

- If dispensing Capsule Toys the portion setter needs to be removed altogether to make it big enough to except the capsules used to dispense the toy. Note: Removing portion setter does not need to be done for Bouncy or Super Balls.

- Once you have the desired settings on your portion wheels put the wheel back in the hopper. Place the brush plate over the wheel with the springs located over the hole in the hopper. If the machine leaks candy for no reason the brush plate has been put in backwards. Replace the canister on the hopper and replace the 4 corner screws making sure they are snug.

- Every time you reset the candy portion setter plastic adjustment plate you will have to run quarters through the machine to see if it's the correct amount of candy you want the machine to dispense. If not, change your candy portion setter plastic adjustment plate to a different portion setting and test again.

- When setting the candy portion setter plastic adjustment plate on your machines do not expect it to give out the exact same amount of candy on each and every vend/sale. The amount of candy that the machine dispenses will vary slightly on every vend/sale. All bulk candy machines operate this way, so don't let it concern you.Remember Candy/Snacks cannot be dispensed through a gumball wheel and Gumballs/Toys cannot be dispensed through a candy wheel.

- As you are adjusting the portion setting size on your Candy/Snack wheel it is easier to test the portion size you are giving with each vend/sale by putting the candy wheel flat on the table. Take the candy/snack you will be selling through that canister and fill the candy wheel up to the brim of the candy well. Do not overflow. Once the candy wheel is put back into the machine the brush plate will brush any candy above the candy wheel off so for testing do not over-fill the candy well or you will not get a good count. Once the candy well is filled lift the candy wheel up and the candy that is in the candy well will sit on the table ready to be counted. If the count is not the right amount adjust the portion setter right or left until the desired count is correct. Once you have the count you want then put the candy wheel back into the machine as previously explained. Make sure you run quarters through the machine once you are done to do a final test on the count and to make sure the machine is ready to go for your customers.

- Candy Wheel with Filled Candy Well

- Removed Candy Wheel to Count Candy

8. Transporting Your Machine to a New Location

- Following the instruction in your Owners Manual, assemble the floor stand to the machine. Make sure that everything is ready to go.

- Do not fill with candy until the machine is on location. If you fill the machine with candy it will add another 30 lbs. to the machine and make it difficult to carry.

- Once the machine is assembled, put the plastic bag and the box that the machine came in back onto the machine. This will protect your machine until it is on location.

- The machine will travel in the back seat or rear of a vehicle. Lay the machine down on the back seat or rear of your vehicle. Make sure that it is secure and won't move.

- Wrap a blanket or towel around the base of your stand to protect the base from scratches and to protect the vehicle upholstery.

- Once you get the machine to the location, carry it in and place it where it will remain. Remove the box and the plastic from the machine and fill the machine with product . Set the feet of the stand by unscrewing them to make the machine stable and not wobble.

- Make sure that the product you have chosen matches the dispenser in the canister. For example gumballs will not vend correctly through a candy wheel and candy will not vend correctly through a gumball wheel.

- Once the canister is filled and before you replace the canister back in the machine, check to make sure the dispensing wheel is in the right position by looking under the canister hopper at the hole. Make sure the candy or gumball well is centered in the middle of the hole.

- Wipe the machine down and make sure everything looks good and presentable. It is good to run a quarter or two through each of the coin mechanisms to make sure they work and correctly dispense product.

- Note: In some locations it is nice to take a small baggy or 2 and give the person allowing you to be at that location a small portion of their favorite candy.

- CANDY