The Spiral Gumball Machine has set the standard for quality and innovative design in the vending industry. This is no ordinary machine! The excitement really begins when the first coin is dropped into the coin mechanism and the gumball comes racing down the clear, sloping, spiral track. That's when the fun starts for you too! Presented here is information and detailed illustrations to help familiarize you with your new spiral gumball machine. The information and illustrations presented here in the owner's manual will make normal servicing and minor repairs of your new machine much easier.

How to Assemble a Spiral Gumball Machine?

Tools Required

- Spanner screwdriver (provided)

- Needle-nose pliers

- 3/8 wrench

- 7/8 wrench

- 5/64 Allen wrench

Steps to Assemble Spiral Machine

- Place the base of the machine on the ground. Gently place the cylinder on the base with the seam of the cylinder above the cash door. The cylinder is notched at the seam fitting directly over the "locating point of the base" above the cash door.

- Place the spiral tray assembly in the cylinder with the notch of the center tube tray assembly ("the tree") directly over the locating point of the center hole in the same fashion as they cylinder.

- Place the head of the machine on the cylinder. The locating point of the head should fit securely into the notch of the cylinder.

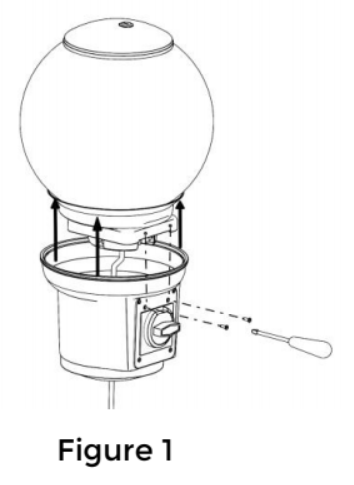

- The clear coin/gum diverted can now be placed into the head at this time. The "U shaped" upper crossbar should now be lowered into the head. The center rod can now be inserted through the crossbar. The lower crossbar should be placed into the base at this time located at the back of the center tube towards the cash door. Tighten the 3/8" coupler nut at this time. Do not over-tighten the coupling nut, this could damage the base. See Figure 1.

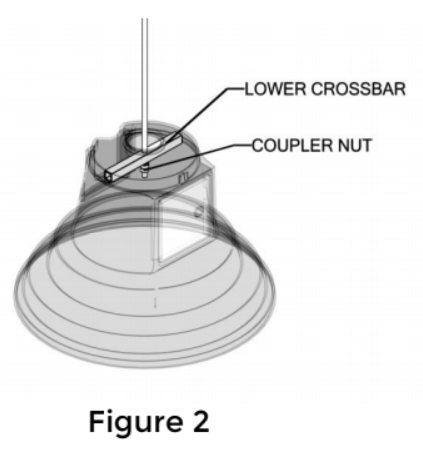

- The machines have a secured tray for deposited coins in the base of the machine. It has a separate lock from the lid and allows you to collect money without disassembling all the rest of the machine. Check the lock operating before placing on the rout. See Figure 2.

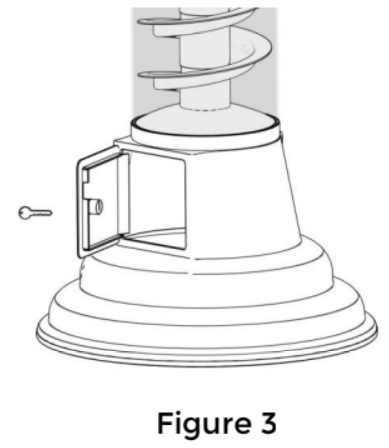

- Lower the globe over the rod and secure to the faceplate with the spanner screws provided (see Operating section to make sure the hopper assembly is properly timed) as seen in figure 3.

- Drop several gumballs into the globe and deposit quarters in the coin mechanism to ensure the machine is properly timed and functioning correctly. The hat can now be placed over the globe securing the machine and globe as one unit.

Steps to Disassemble Spiral Machine

- Remove the hat from the machine with the key provided. Turn the key counterclockwise to release the lock from the center rod. Push down firmly while turning the key.

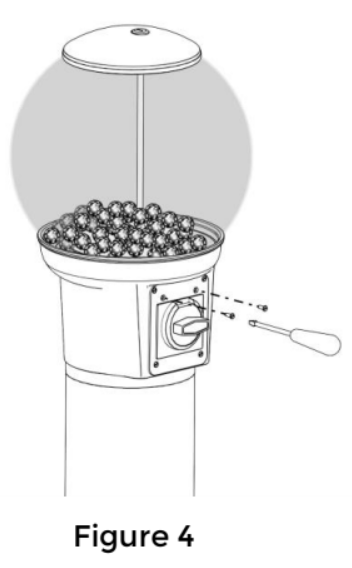

- Release the globe from the machine by removing the two spanner screws directly above the coin mechanism with the spanner screwdriver provided. Lift the globe veritcally over the center rod. NOTE: the product does not have to be emptied from the globe for removal. See figure 4.

- Open the cash door with the key provided pushing firmly and rotating a quarter turn counterclockwise. Loosen and remove the 3/8" coupler nut attached to the rod. Remove the lower crossbar.

- Remove the neon tubes from the machine by gently pulling vertically through the head of the machine. Remove the rod and upper crossbar.

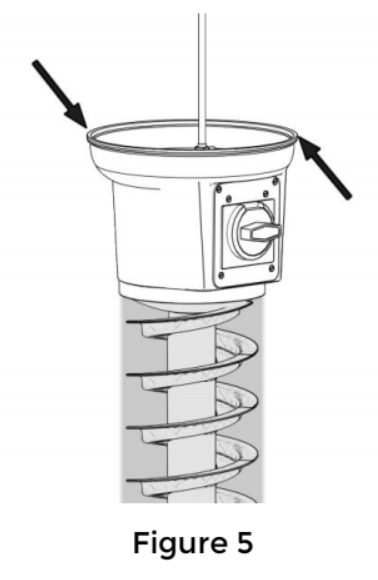

- Remove the head by holding one side and gently tapping the other side at a slight angle to break the seal securing the head to the cylinder. See figure 5.

- Remove the cylinder from the base with the tree still inside the cylinder. The spiral tray assembly can now be removed. CAUTION: Do not try to pull the spiral tray assembly through the cylinder, gently push downward to not scratch the cylinder.

Operating Instructions

- Adding Balancing Weight to Base: Sand must be added to the base for stability. To do this, first visit your local Specialty Hardware Store and purchase a Rubber Plug at least 1" in diameter. While the machine is empty, lay it on its side and drill a hole in the bottom floor to fit the size of the purchased rubber plug. Fill with sand and insert rubber plug. This will add about 30 lbs. for stability.

- Emptying Coins or Tokens: Open the cash door at the base of the machine with the key provided and remove the coin box.

- Filling the Machine: Gumballs, especially when cold, may break or crack when the gum is loaded too quickly. If possible, have one other person hold the machine at an angle when filling. Pour the gum slowly from the bag and remove any which may be broken or deformed.

- Locks & Keys: Please exercise caution and do not over-tighten the lock on the top of the hat. This can strip the threads if you over-tighten the lock.

- Timing of Hopper: To adjust the timing of the hopper, the globe must be removed, and the three-hole gum wheel rotated to the proper position. See Figure 6.

Cleaning & Maintenance

- Plastic Parts: Cleaning of plastic and acrylic parts can be done with glass cleaner or mild soap and a soft cloth. DO NOT use an abrasive cleaner or paint thinner.

- Fiberglass Head & Base: Mild polishes and waxes remove most scratches and marks. Gently apply the compound with a soft rag and apply in a circular fashion.

- Globe: The globe is constructed of an acrylic polymer. Paint thinner and acetone will dull and break down the plastic. Do Not Use these compounds. A mild plastic polish or glass cleaner is recommended.

- General Maintenance: The 3/8 coupler nut and spanner screws will generally need to be adjusted and tightened. Do not over-tighten the screws because this can pull the inserts from the fiberglass or strip the threads.

Troubleshooting Guide

- Gum Won't Come Down: This problem is caused by either (a) a deformed piece of gum or (b) the wheel riser has slipped and spun to the side, closing off the delivery hole. Remove the globe and check to see that the delivery hole is not closed off, or gum caught in delivery hole.

- Inconsistent Gum Delivery: This problem is caused by either (a) the hopper assembly timing being off or (b) the lateral springs of the hopper assembly are broken. Remove the globe and check the timing, check to see that the springs are attached above the delivery hole.

- Quarters Stuck in Spiral Tray: This problem is caused by the gum guide and coin/gum diverter not being properly aligned. Remove the globe and check to see that there is no interference between the two.